Our industry has focused on operational carbon for years. For example, we can replace the mechanical, electrical and plumbing (MEP) systems with more efficient technology, but what about the building materials already in place? If the industry is to meet our near-term climate goals, focusing on embodied carbon is critical.

Embodied carbon consists of all the emissions associated with the extraction, manufacturing, installation, maintenance, replacement, repair and eventual decommissioning of building materials. While the efficiency of building systems continues to improve and the energy grid continues to decarbonize, studies show it currently takes about 30 years for the average building to emit as much operational carbon as what was embodied in the building before those systems were even turned on. Even though we can’t change what we did in the past, we can focus on the future. This includes thoughtful design that optimizes the amount of material used in our buildings and encourages innovative manufacturing for the production of reduced carbon products at the source.

Measuring Environmental Impacts

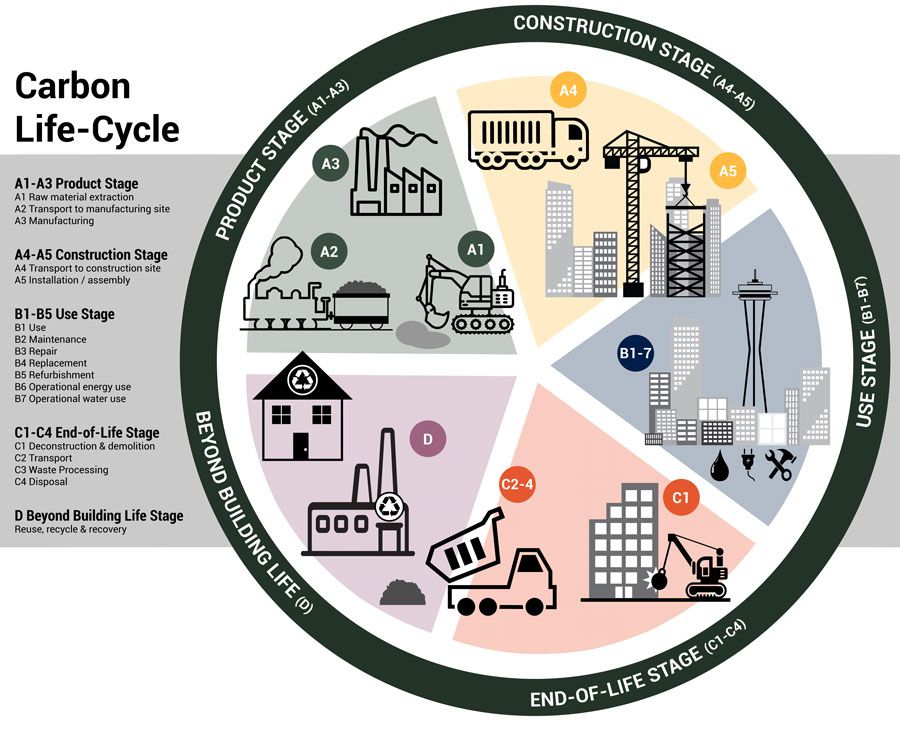

We measure the environmental impacts of a building through a life cycle assessment (LCA). This systematic analysis measures the associated emissions at each of the five life cycle stages: product, construction process, use, end of life and the potential benefits and burdens beyond the system boundary.

Performing an LCA of a building’s environmental impact from beginning to end gives us a more complete picture and will help us make informed decisions when it comes to reducing carbon emissions.

A Focus on Concrete

Concrete is the second most consumed material in the world — second only to water.

At this time, the amount of concrete on a project typically drives the embodied carbon footprint and cost. It’s present in nearly every building, most commonly for its use in foundations. In commercial projects, concrete is increasingly more prevalent in floors or topping slabs for durability, and especially where needed for lateral support systems in taller buildings or those in high seismic zones. Looking ahead, as seismic design requirements for concrete become more stringent, the industry is increasingly turning to lighter materials like steel and wood to reduce overall building weight and structural loads. While this shift won’t eliminate concrete from our buildings, it will inadvertently lower embodied carbon emissions in affected structures and could make incorporating heavier concrete elements more costly in the future.

Embodied Carbon in Cement

The cement industry accounts for 8% of global greenhouse emissions. And although cement comprises 10-15% of the overall concrete mixture weight, it makes up 80-85% of the mixture’s overall carbon emissions. The key to achieving reduced carbon concrete is through minimizing the amount of cement needed or replacing that cement with other materials while meeting the same performance requirements.

The main source of carbon emissions from concrete production is associated with the energy-intensive processes used in order to create clinker, the major ingredient in cement. The other part is simple chemistry — carbon dioxide, a greenhouse gas, is directly released as a product of the chemical reaction while creating clinker. Although there are efforts on the supplier side to adopt alternate manufacturing processes, these are not yet commercially available, so our biggest opportunity to reduce embodied carbon today is to minimize the amount of cement needed from a design and procurement standpoint.

However, the materials we’ve traditionally used to replace cement are byproducts of high-energy processes like burning coal or smelting steel, and these are becoming limited. To meet demand, these byproducts are increasingly being imported, adding even more to their mixture’s carbon footprint. On the other hand, suppliers across the country are starting to reduce their reliance on conventional byproducts by utilizing new materials such as Portland limestone cement, ground glass and natural pozzolans to replace cement while meeting similar performance requirements.

Looking ahead, new technologies designed to address the main issues of CO2 off-gas and high energy demand during cement production are on the rise. Although most of these technologies are not yet widely available, companies like Sublime, Brimstone, Blue Planet and Heidelberg are actively increasing access to reduced carbon concrete solutions through alternate cement production methods and carbon capture in the near future, which is good news.

Steps to Take

During design, it’s important to coordinate column grid layouts and loading in a way that optimizes the structural systems and reduces the concrete needed overall. For multistory buildings, floors usually require the most material and contribute significant portions of the overall embodied carbon. There are several different materials and framing layouts engineers can utilize, but they are highly dependent on construction types and practices that are most conducive to the project type and cost-effective in the region.

In the case of concrete, cement content is directly tied to compressive strength, so it’s good practice to try and reduce strength of concrete elements as much as possible while keeping in mind the minimum strength requirements dictated by potential exposure classes. However, it’s also important to keep in mind that this relationship is not so straightforward when introducing reinforcement for high demand concrete elements. There are several different ways to design reinforced concrete elements so the structural engineer should consider the optimal way for these materials to work in tandem while balancing the goals of the project.

Performance-Based Specifications

Once the performance criteria for concrete is finalized by the design and construction teams, the next step is to coordinate with the suppliers and encourage further mix design optimization. We can coordinate with suppliers to optimize cement in the mixture, but we must be mindful and adhere to their comfort level with quality assurance.

It’s also important to keep in mind that not every supplier has unlimited slag, fly ash or whatever cool technology you’ve heard about recently. So weighing the impact these strategies have through comparison of Environmental Product Declarations (EPD) is a must. And here’s why: EPDs are like nutrition labels for building materials, with the Global Warming Potential (GWP) or embodied carbon being our “calories.”

GWP limits can be utilized in specifications to ensure compliance with policy or project requirements, but the best way to ensure the lowest carbon mixture is procured at an economical price point is through coordinating directly with the supplier, general contractor and the design team to spur optimization.

If coordinated routinely throughout the design and procurement process, there is a high chance of achieving cost-neutral reduced carbon concrete or even saving costs through the reduction of cement.

For more information on reducing embodied carbon, contact Jessica Martinez, structural sustainability specialist with DCI Engineers at jmartinez@dci-engineers.com.